Workshop on applicable Bio-CC(U)S concepts for member states 2030 – 2050

Publications

Background

The Task 41 Special Project on Bio-CC(U)S was established under the IEA Bioenergy Agreement as a cooperation with the IEA GHG R&D Programme. The special task consists of four specific workshops concentrated on various aspects around Bio-CC(U)S. The main purpose is to shed light on the role of Bio-CCS regarding efforts to reduce atmospheric CO2 emissions. Another goal is to evaluate how to boost Bio-CC(U)S initiatives in member countries. The final outcome of the Task 41 special project is a roadmap on commercial implementation of Bio-CCS.

The first IEA Bioenergy Task 41 workshop was organized in Oslo in May 2016. The topic of the workshop was Applicable Bio-CCUS concepts for member states 2030–2050 – Technological and financial aspects of Bio-CC(U)S. The workshop was hosted by Miljøstiftelsen Bellona. The workshop included a site visit to the CO2 capture test facility at the Oslo Municipality Waste to Energy Plant at Klemetsrud.

The objective of the workshop was to give an update on the status of national plans and roadmaps for Bio-CCUS in member states. The scope of the workshop focused on the role of Bio-CCUS in EU towards 2030 and 2050.

Bio-CCUS

The term Bio-CCS describes processes that include biomass with carbon capture and storage. Carbon capture and storage related to fossil fuels (fossil CCS) typically only decreases the rate at which carbon dioxide (CO2) is entering the atmosphere. CCS can achieve nearly zero emission at best. Bio-CCS, in contrast, can achieve a net removal of CO2 from the atmosphere. Growing biomass binds atmospheric carbon during photosynthesis. Capturing CO2 during biomass conversion and storing it in geological formations enables extraction of CO2 from the atmosphere. This activity results in net negative emissions. Bio-CCS can also remove historic CO2 emissions as well as CO2 emissions from other sectors and sources from the atmosphere. The terminology of Bio-CCS in the literature is not fully consistent. Both Bio-CCS and BECCS (bioenergy and carbon capture and storage) are used more or less interchangeably. However, Bio-CCS usually has a wider context, whereas BECCS is used more in relation to power production. Bio-CCU (biomass with carbon capture and utilization) describes the use of the captured biogenic CO2 as raw material for the production of fuels, chemicals or other materials. In this case, carbon storage is usually only intermediate, with varying time frame depending on the product. For Bio-CCU net emissions are not necessarily negative, as release of CO2 can occur at the end of the product lifetime.

Deployment

Around 1 500 Gt CO2 is still bound in non-harvested global fossil fuel reserves. It is estimated that 800 Gt of this could still be released, but this means that almost half of the reserves will have to stay put under ground. This leads to a concern about not only making the Bio-CCS technology available, but also to consider what kind of distributional consequences large scale implementation will have on the economy.

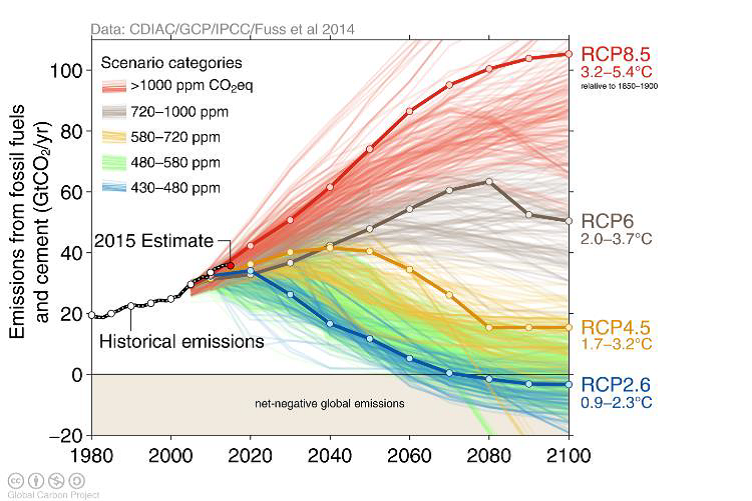

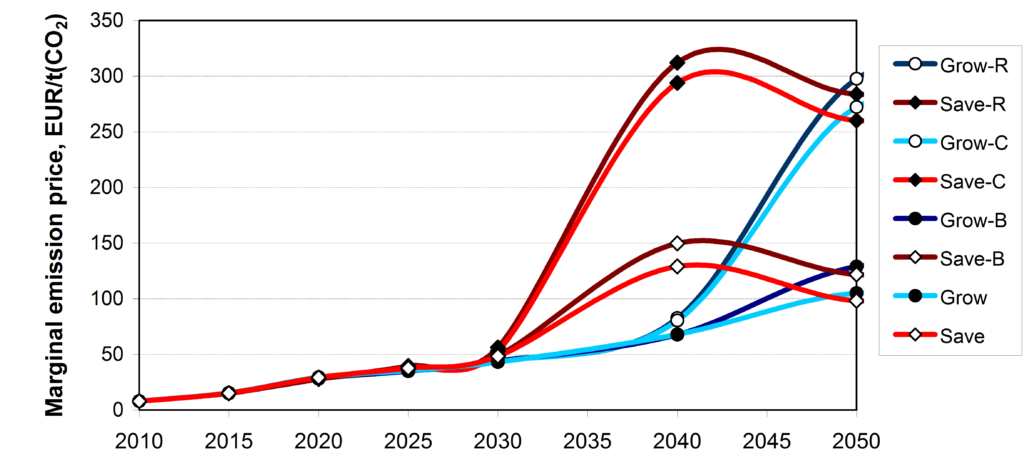

In order to meet the ambitious goals from COP21 in Paris, and according to system studies by the IPCC, there is an urgent need to realize negative CO2 emissions in developed countries. Regardless of how the future emission scenarios are constructed, negative emission technologies (NETs) and particularly Bio-CCS play a significant role. A key factor in this respect is the timeline of commercial implementation of carbon negative technologies. Current scenario modelling suggests that deployment of Bio-CCS will be rapidly ramped up only after 2030. The main reason for this is a general realization of the need to decrease emissions in order to reach well below the 2°C trajectory. There are only few pathways to reach the 2°C apart from Bio-CCS or BECCS, including energy efficiency and fuel switch, and the door to securing the 1.5°C is basically closed. What is important to remember is that the time span between commercial implementation of Bio-CCS and achieving net negative CO2 emissions is tens of years. As a consequence, commercial implementation of Bio-CC(U)S today would enable net negative emissions to occur only at the end of the century. This calls for an urgent deployment strategy for negative emission technologies. Both the CO2 emission rate and the cost of carbon removal will see an explosive growth after 2030 (see Figure 1 and Figure 2), increasing rapidly the longer the commercial implementation is delayed. The sooner Bio-CCS becomes commercial, the greater is the negative impact over time. With this time range it is also clear that the importance of CCS in Asia and non-OECD countries will increase.

Figure 1 Negative emissions in the AR5 (Fuss et al, Betting on negative emissions, 2014)

Figure 2 Cost of emission reduction as a function on time for commercial deployment in the EU (Low Carbon Platform, 2016)

New scenarios are expected to be published in 2017, but it is clear already that the need for negative emissions will be even more dramatic after 2050 towards 2100. In the current light of actions, will the technology development and deployment be able to keep up with the required need? Are we able to ramp up the impact with current demonstrations?

In summary, timely deployment of Bio-CCS projects is of significant importance, the main reasons being:

- Current mitigation scenarios rely heavily on bioenergy with and without CCS

- Deployment lags critically behind, so in order to enable large net negative emissions by the end of this century we need to kick-off CCS and Bio-CCS now

- There might be limitations in Bio-CCS deployment, and these need urgent clarifications

- The unavailability of Bio-CCS will lead to more painful and costly decisions in other sectors and in all sectors in the long term

Importance of first movers

Biofuels production, biogas and CCS in association with waste incineration were identified as the most potential first applications in Europe. Some of these industrial sectors have already initiated CCS activities, such as the waste-to-energy plant at Klemetsrud, Oslo, and in the Netherlands.

The combination of waste incineration and CCS is often overlooked as a potential option for (Bio-)CCS demonstration projects. However, this could be an important platform for establishing demonstration projects. The waste-to-energy industry has broad experience in operating according to tight emission regulations with cost implications that follow. In addition, the industry is not typically operating in fully liberalized markets, and the plants are often owned by communities. Also the scale of the installations is appropriate for CCS demonstrations. Important regardless of the industry sector, however, is clear, long term commitment from policy makers and incentives for the industries to realize commercial deployment.

The main focus for application of CCS has so far been concentrating on the power sector. Key words for breaking down the development have frequently been efficiency penalty and costs. In the waste-to-energy industry the primary objectives have been to dispose of waste in the cleanest and most useful way, and concerns around energy penalty and costs have typically not been the most prioritized issue. For the waste-to-energy industry CCS could in fact bring an even cleaner image.

An existing European initiative on Bio-CCU is a waste-to-energy plant in the Netherlands where waste from United Kingdom and the Netherlands is combusted. CO2 captured from the flue gases is used for nearby horticulture. The scale of the project is 50 000 t CO2/a.

Another example of an existing Bio-CCS project is from Illinois, US. CO2 is captured from corn fermentation for ethanol production and stored underground. CCS in the US oil industry has a strong policy support in terms of enhanced oil recovery (EOR), which facilitates deployment of the technology.

Algae projects (ocean carbon sinks), seaweed and gas fermentation processes also have potential for Bio-CCU by for instance recycling carbon in off-gases to fuel.

Natural first movers to take the lead in deployment of Bio-CC(U)S would be countries who have the conditions for cultivating substantial amounts of sustainable biomass that doesn’t conflict with other land uses. In order to map the realization potential thorough, regional studies are needed.

Challenges

Bio-CC(U)S is technically feasible and realizable today. One of the challenges of Bio-CC(U)S is that most of the CCS initiatives have been focused on the coal-fired power sector. In addition, Bio-CC(U)S is currently happening at very small scale, up to 1 MTPY CO2. Larger scale installations will be needed in order to demonstrate the technology. There is an urgent need to address the non-technical issues, such as financing and regulations concerning negative emissions.

A key concern for Bio-CC(U)S is the availability and use of sustainably grown biomass. Biomass used in Bio-CC(U)S installations might compete with natural resources and food for land use. In addition, use of biomass which is not grown and harvested in a sustainable way could even increase CO2 emissions. As a consequence, rather than technical challenges, the main challenges for Bio-CC(U)S are driven by the increased complexity of the entire CCS chain (from biomass raw material supply to CO2 storage), regulatory and financial gaps, and public perception.

Storage and transport infrastructure is one of the biggest bottlenecks for larger (Bio-)CCS applications and deployment, as CCU “CO2 sinks” are currently only available at a small scale.

Another essential uncertainty is how natural systems and the carbon cycle dynamics will respond to a large removal of carbon. Also the exact role of deforestation/afforestation and their potential of binding CO2 in biomass is not clearly understood. Land use for realizing afforestation potential of binding CO2 is large, and will for instance increase competition for land use.

Communication with stakeholders

Liaising with stakeholders is a key to implementing Bio-CCS. Moving the bioenergy and CCS communities to act in concert and clarifying public perception (“social license” to operate) will be vital for implementation. It is important at this moment to provide a clearer and consistent message to stakeholders concerning the potential role of Bio-CCS. It is also important to get a clear understanding of the requirements for full commercialization of Bio-CCS. Currently, there are clear differences in the results of modeling work addressing the role of Bio-CCUS. In terms of contribution to climate change mitigation the range of results obtained varies from limited to significant. The discussion in the workshop highlighted the importance of starting Bio-CC(U)S deployment well before 2050 if we are to get the high penetration wedges needed after 2050.

Recommendations

- Get a good understanding of realistic potential of the different solutions with associated costs

- The policy framework should enable low threshold implementation of first mover projects. This would support both the deployment of negative emissions and development of CCUS technologies.

- There is a need for funding of non-technical projects that address the complex nature of Bio-CC(U)S deployment

- More thorough studies on advantages and disadvantages of Bio-CCS such as capacities, trade-offs, impacts, etc.

- CO2 storage (confidence) remains an issue for Bio-CCS as it does for conventional CCS and must therefore be managed at higher levels than project-based. The waste-to-energy plant EGE at Klemetsrud serves as an example of this.

- Government and public funding must take an active role in establishment of CO2 hubs and larger infrastructure in order to facilitate the entire CCS value chain from capture to storage. This would enable the participation also from smaller companies who alone will not be able to establish a CCS chain. Several companies and installations have expressed interest in CCS if storage would be provided. This would also enable players to emerge on the storage side of the value chain, if sufficient business (CO2 stream) would be available.

Looking ahead

In this first IEA Bioenergy Task 41 workshop on Bio-CC(U)S the sustainability of biomass and the current policy framework were key points raised. It is essential to establish the possible positive and negative aspects connected to Bio-CC(U)S in order to get a clear picture of the strengths and weaknesses of Bio-CC(U)S technologies.

The second workshop of the IEA Bioenergy Task 41 on Bio-CC(U)S will be held in Lausanne in connection with the GHGT-13 conference. The topic of the workshop is Sustainability and GHG impact of Bio-CC(U)S. The workshop is a side event of the official GHGT-13 program and is open to all interested parties.

Site visit to Oslo waste-to-energy plant at Klemetsrud

The city of Oslo has taken on an ambitious sustainability vision for the waste management division. Among other goals CO2 emissions will be reduced by 50% within 2020 and 95% within 2030. The plan is to use carbon capture and storage technology to reach this target. The waste management of Oslo consists of two optical sorting plants, one biological treatment plant and two waste-to-energy plants. The IEA Bioenergy Task 41 workshop visited the waste-to-energy plant at Klemetsrud just south of Oslo.

The Klemetsrud waste-to-energy plant has a capacity of 310 000 t/a and currently produces 175 GWh/a electricity and 750 GWh/a heat. An extensive CO2 capture study was undertaken for the Norwegian Government during 2015-2016 where carbon capture from cement production, fertilizer production and waste incineration was studied. The study also contains an evaluation of CO2 transportation and storage options in the North Sea. The study is available in Norwegian at https://www.regjeringen.no/globalassets/departementene/oed/pdf/mulighetsstudien.pdf

50 – 60% of the CO2 emissions from the Klemetsrud waste-to-energy plant are of biogenic origin. This enables the plant to become a forerunner in implementation of Bio-CCS. A major opportunity for the waste-to-energy plant in terms of Bio-CCS is the stability of the waste treatment industry. Waste-to-energy is a local business rather than a global undertaking and thus not likely to be at risk of carbon leakage. Specific challenges for the Klemetsrud plant include the availability of cooling water, whether there is sufficient area available for the CO2 capture plant on site, questions concerning CO2 transportation from plant to port which will go through a densely populated area, funding issues and obstacles related to the public and regulatory concerns.

A mobile test rig for post-combustion capture of CO2 from the flue gases has been applied to the Klemetsrud plant showing promising results. Both conventional amine absorption technology and ammonia-based absorption have been tested. Initial estimations of CAPEX amount to 200 – 250 M€ and operational expenditures to 15 – 25 M€/a.

The carbon pricing remains an open question in a possible CCS value chain. The initial plan is to capture 300 000 t/a CO2 from the plant at Klemetsrud that has received investment support and where the carbon price is set at port. Other options include selling carbon quotas for green carbon and carbon pricing on products or for delivery.

Technological and financial aspects of Bio-CC(U)S by 2030-2050